Summary

- Cluster consolidation strategies for solid oral forms in multi-product establishments

- Biocidal regulations applied to the disinfectants used in the pharmaceutical industry: all you need to know…

- Cryogenics is the study and production of low temperatures

- Cleaning Validation for biotechnological substances : What acceptance criteria ?

- “Health-based approach” implementation for setting limits in cleaning validation for Vaccines/Biotech

Cryogenic cleaning enables all materials to be cleaned of any thickness of dirt, without abrasion, without water, without solvents, without secondary waste and often without disassembly.

It can be of interest to the pharmaceutical industry where strict conditions of cleanliness are mandatory.

How does it work?

By blasting (pneumatically) pellets of dry ice (at Mach 3/4 and at -78.5°C) onto a soiled material, at 20°C,

– the dirt is chilled, locally, rapidly and profoundly, fractures then disintegrates on its substrate,

– the pellets are forced to vaporize (their volume transforms instantly from that of a grain of rice to that of a cup of coffee, that is 800 times larger) in millions of micro-explosions of gas…

This CO2penetrates the cracks at high speed and high pressure; the dirt is literally blown off its substrate; it then falls under the effect of gravity and the CO2 returns to the atmosphere.

Two major advantages in pharmaceutical production:

– Cryogenic cleaning does not use water, which means it can be used for cleaning electrical cabinets, electronic boards or subassemblies, complete production lines and fans, etc. Cryogenic Cleaning is a dry-cleaning technique: no water, therefore no microbial growth, therefore no biofilm, therefore no corrosion, therefore no drying time (and no need to store solvents in a ventilated room that complies with the standards, etc.).

– CO2 is an inert gas which, unlike water and solvents, will not bind to any chemical compounds. This is also a major advantage in pharmaceutical production.Cryogenic Cleaning does not generate any secondary waste (which must normally be removed at high cost), unlike laundry products and detergents.

The other advantages

– a zero carbon footprint: the CO2used for cleaning would have otherwise polluted the atmosphere. Cryogenic cleaning gives it a second life. In addition, as no solvents are used, we avoid the CO2that is generated by their manufacture and by that of wipes, canisters and containers, etc. The carbon footprint of Cryogenic Cleaning is better than zero!

– A single cleaning technology for all soils (ink, varnish, paint, grease, organic deposits, dyes, rust, etc.), on any substrate (glass, plastic, plexiglass, metal, concrete, 304/304L and 316/316L stainless steel, EPDM, PTFE, silicone, etc.) without ever damaging it (as a result of vaporization on impact, what reaches the substrate is CO2 in gaseous form and the gas is not abrasive). Hence the reduced downtime compared with current cleaning technologies.

– Accessories for cleaning over the whole spectrum of requirements:: from ultra-gentle (Cryogenic Cleaning does not damage the surface condition of stainless steel and other materials with a specific Ra value) to hyper-aggressive.

The disadvantages of Cryogenic Cleaning

– Cryogenic cleaning is noisy (75-100dB): auditory protection reduces this noise by 25dB.

– Cryogenic cleaning generates aerosols: protection of sensitive areas (containment airlock).

(Preventive) cleaning possibilities in pharmaceutical production.

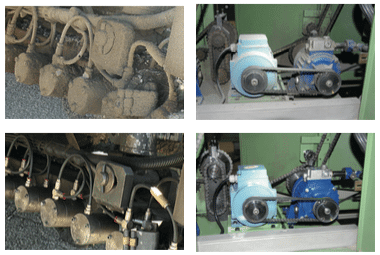

Removal of labels from shuttle boxes, cleaning of gratings, of floor weighing systems, cleaning of production lines (conveyor belts, hoppers, containers, etc.), electrical cabinets, radiators, electrical circuits, fans, emulsifiers, mixers or agitators, reactors, drying stations, packaging stations, shuttle boxes, manufacturing lines of capsules containing drugs (molds and micromolds of presses heat cleaned, without disassembly and with no damage), cap stamping stations, counting, weighing, detection stations…

Contact persons:

This technology is of interest to Maintenance Managers as well as Quality Assurance, Manufacturing, Packaging Managers, etc.

Cryogenic Cleaning represents a universal solution for cleaning installations, production, drying, stamping and packaging lines, etc., used in pharmaceutical production. It allows the kind of preventive cleaning that is required for optimal use of production tools.